WASA-BI MOTOR

PARTAGEZ VOTRE PASSION

Smooth, fast and safe !

Fluidity

Fly with the new Wasa-Bi, where "easy take off" is more than just an expression, it’s a promise! Thanks to its optimized design for motorized flight, it guarantees you a smooth take-off, even when loaded, and impressive handling. From the first moments of flight, you will feel an incomparable lightness and fluidity, from the start to the landing. Every flight becomes a unique experience, combining comfort and pleasure.

Speed

With the Wasa-Bi, rediscover the sensation of speed in motorized flight. Its ability to penetrate the air without effort and its top speed reinvents the idea of air travel. Designed to maximize engine efficiency, it takes you faster and farther while maintaining a unique flying finesse. Speed yes, but without recklessness. At ITV Wings, safety is our priority. We have integrated the best passive and active safety technologies to ensure that every flight experience is done with complete peace of mind.

Safety

The Wasa-Bi is a robust and stable wing, even in the most demanding flight conditions. In the event of turbulence, its design guarantees a stability to all tests, thus ensuring a smooth ride at all times. Made with premium materials, this model is designed to last and accompany you on many flights. Available in two colours and three sizes (40, 42 and 44).

colors

Total inflight weight

technical data

| WASA-BI | 40 | 42 | 44 |

|---|---|---|---|

| Surface à plat (m²) | 40 | 42 | 44 |

| Poids voile (kg) | 8.2 | 8.4 | 8.6 |

| Allongement à plat | 5.6 | 5.6 | 5.6 |

| Nombre de cellules | 55 | 55 | 55 |

| Poids Total Volant parapente (kg) | 110-210 | 110-220 | 120-240 |

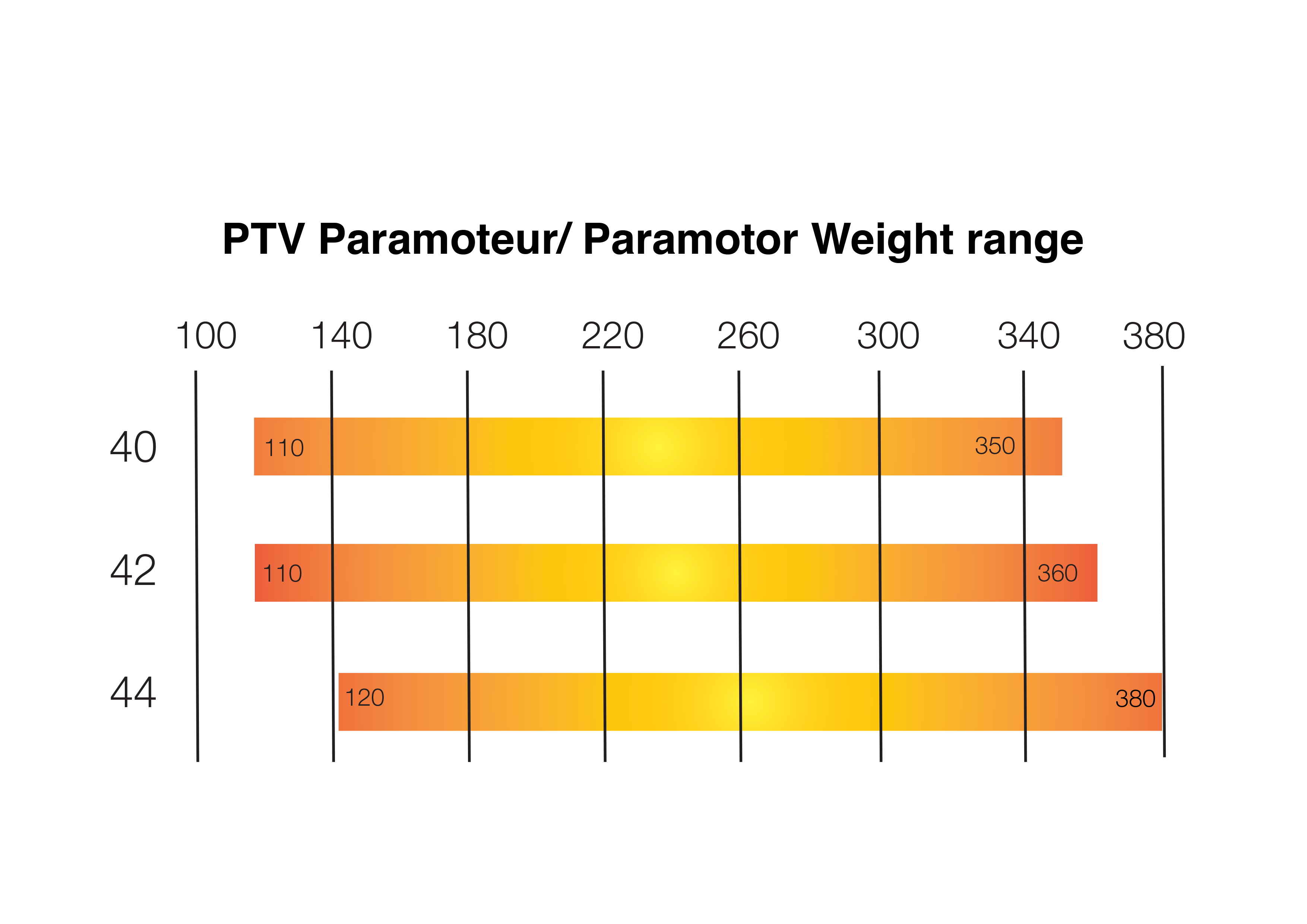

| Poids Total Volant paramoteur (kg) | 110-350 | 110-360 | 110-380 |

| Vitesse bras hauts (km/h) | 40 | 40 | 40 |

| Vitesse max (km/h) | 55+ | 55+ | 55+ |

| Homologation | EN-B / DGAC | EN-B / DGAC | EN-B / DGAC |

Technology

ILT - LASER TECHNOLOGIE : Toute la précision de la découpe LASER des différentes pièces qui composent votre aile ITV.

IRS- SYSTEME DE RENFORT JONCS : Renfort structurel du bord d’attaque par l’intermédiaire de joncs nylons.

3D SHAPING : Optimisation de coupe et d’assemblage des panneaux qui constituent le bord d’attaque.